(Disclaimer: This article is based on our conversations with Dr R. K. Agrawal, a steel industry veteran with 48 years of experience in steel manufacturing. He has served as an Executive Director at SAIL.)

“Supplier relationship management is instrumental to the growth of an organization.

I know a unique case where a steel plant could not function because of the unavailability of a thyristor at 2:00 AM. When the supplier heard about this issue, he opened his store and delivered the electronic component. The plant was set to work in no time.

In another instance, in a PSU that produces five million tons of steel, the blast furnace ran into trouble because of electrical problems. The supplier sent their expert engineer upon short notice, and the furnace was put into operation in a few hours. It saved the PSU from the loss of several million rupees,” says Dr R. K. Agrawal.

These two cases prove the importance of good Supplier Relationship Management (SRM), a concept introduced by McKinsey consultant Peter Kraljicin in 1983.

According to Kraljic,

Instead of simply monitoring current developments, management must learn to make things happen to its own advantage. This calls for nothing less than a total change of perspective: from purchasing (an operating function) to supply management (a strategic one).

Let’s delve deeper into various aspects of SRM and how to plan an effective SRM strategy.

What is Supplier Relationship Management?

Supplier Relationship Management (SRM) is an instrument to help enterprises build trustworthy and mutually beneficial trade relations with suppliers. It involves a systematic approach to identifying the right supplier with good potential by evaluating their performance based on the goods or services offered. It is also part and parcel of supply chain management and essential for business success.

There are three main types of supplier relationships:

- Partnership: The buyer and seller work closely to achieve desired goals and targets.

- Strategic supplier alliance: Here, the buyer and seller work together to attack the problem till it is solved. Since the outcome is because of joint efforts, both parties willfully share the gains.

- Vendor relationship: In cases of late supply or damaged articles, vendors immediately offer a resolution. Sometimes, they may also compensate the buyer for his trouble.

In many aspects, SRM may sound similar to vendor management. But there’s a fine line between the two.

Difference Between SRM and Vendor Management

| Supplier Relationship Management | Vendor management | |

| Purpose | Establishing mutually beneficial business relations with suppliers. | Establishing costs and service level agreements with vendors |

| Contract type | Strategic. Involves identification of long-term gains for both parties and the means of achieving them. | Generally transactional. Parties may negotiate pricing and terms but only up to a certain extent. |

| Risks | Supplier risks pose a long-term impact on enterprises as it is difficult to find a replacement on similar terms. | Vendor risks impact an organization in short-term as it is comparatively easier to find a replacement. |

In a nutshell, unlike vendor management, any advancement in a supplier’s business largely impacts the organization, and that’s why SRM strategy is essential to create a win-win situation for both.

How to Develop an Effective SRM Strategy

Essentially, SRM involves interacting with and managing third-party vendors that provide goods, materials, and services. It sounds easy enough—you choose suppliers that are cost-efficient and easy to work with.

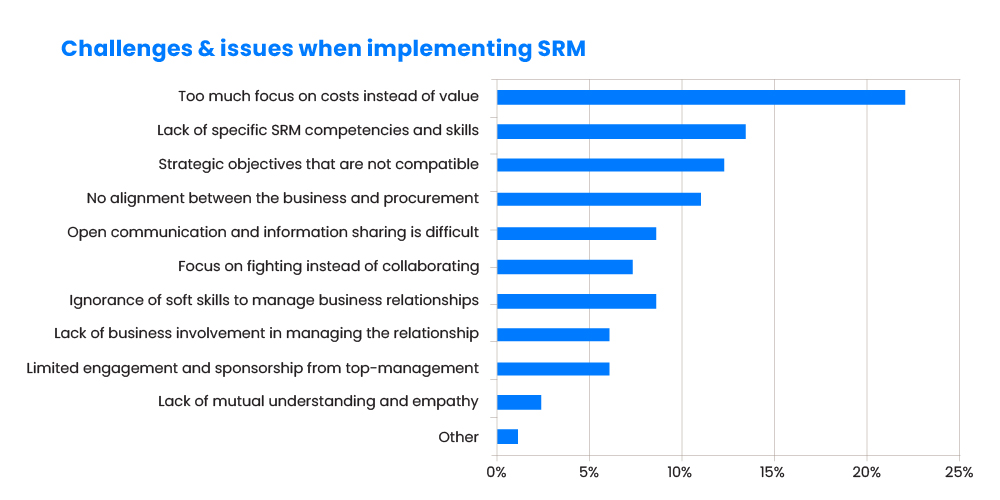

However, too much focus on cost instead of value is the main challenge in implementing SRM, according to a survey conducted by PwC.

That’s why a well-planned supplier relationship management strategy is required. But before, the SRM manager should know supply conditions like:

- Product cost

- The number of suppliers

- Cost of technological improvement

- Changes due to product being obsolete

- Product pricing when an equivalent quality of product is available

- Moratorium due to government policies

- Environmental/external factors which are beyond the control of vendors

The following section illustrates the factors to consider while devising your SRM strategy.

The 5 Crucial Components of a Supplier Relationship Management Strategy

- Defining KPIs

- Segmenting suppliers based on their importance to your organization and the value they bring on the plate

- Preparing SRM strategy for each segment of suppliers

- Executing your SRM strategies

- Measuring supplier performance (SPM)

1. Defining KPIs

It is important to define the KPIs or metrics based on which you’ll evaluate the supplier performance.

Below are the important supplier management KPIs.

- Lead time: The time between a supplier receiving an order and shipping it to the enterprise.

- Compliance rate: It measures the supplier’s adherence to the contract terms. In other words, the compliance rate assesses the extent to which the supplier is able to deliver what they promised.

- Defect rate: It is the measure of damaged/faulty products delivered by the supplier.

- Supplier availability: This supplier relationship management KPI determines whether the supplier is available to fulfil the order as and when required by the enterprise. It also suggests the consistent availability of suppliers during the contract duration.

- On-time delivery rate: This KPI measures the number of times a supplier is able to deliver on time.

2. Segmenting Suppliers

Manufacturers/enterprises deal with many different vendors. Each vendor plays a unique role in the business process, and hence, the strategy for different segments of vendors also differs.

For example, some suppliers keep the Min-Max quantity in the plant premises and raise the bill only after issuing the material.

The popular methods to segment suppliers are the matrix approach and the pyramid approach.

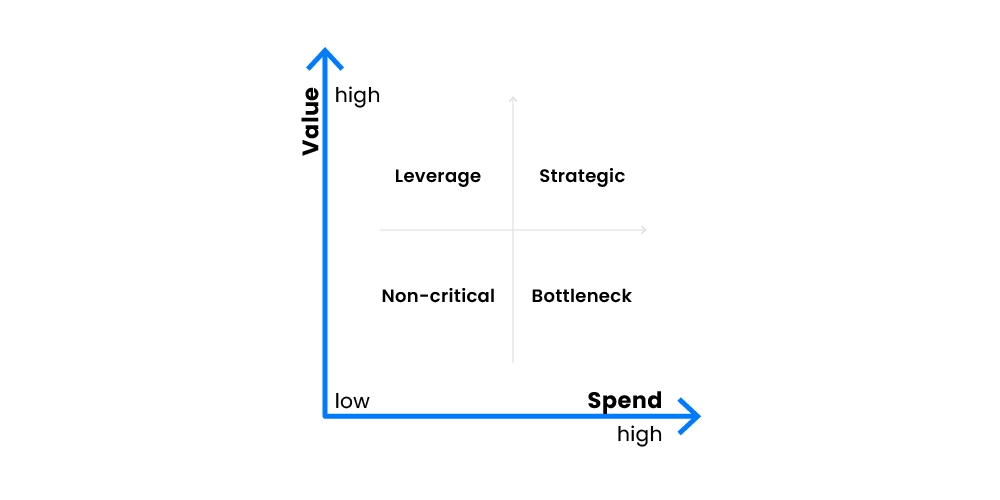

The matrix approach:

In this approach, the suppliers are segmented based on their position in the value versus spend quadrant. Where, value is defined as the importance of supplier for the business continuity.

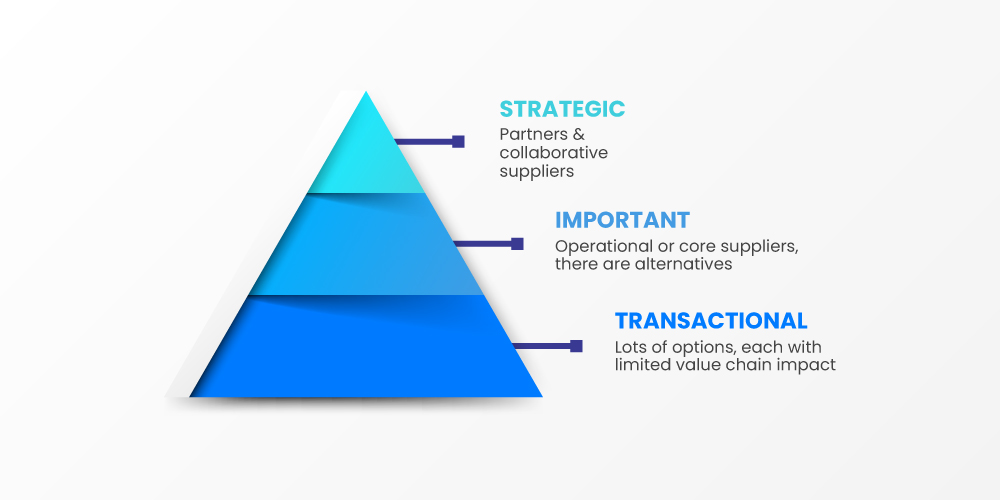

The pyramid approach:

This approach segments suppliers into strategic, important, and transactional categories.

The pyramid approach of segmenting suppliers generally has 3 to 4 tiers. The value of suppliers at the top of the pyramid is more, and at the same time, the option to have similar suppliers is less.

Apart from this, enterprises may segment suppliers based on:

- Discrepancies in projected vs. actual spend

- Supplier’s region of operations and service

- Potential supplier risk

- Scale of supplier’s operations

- The value a supplier brings in terms of innovation or continuous improvement.

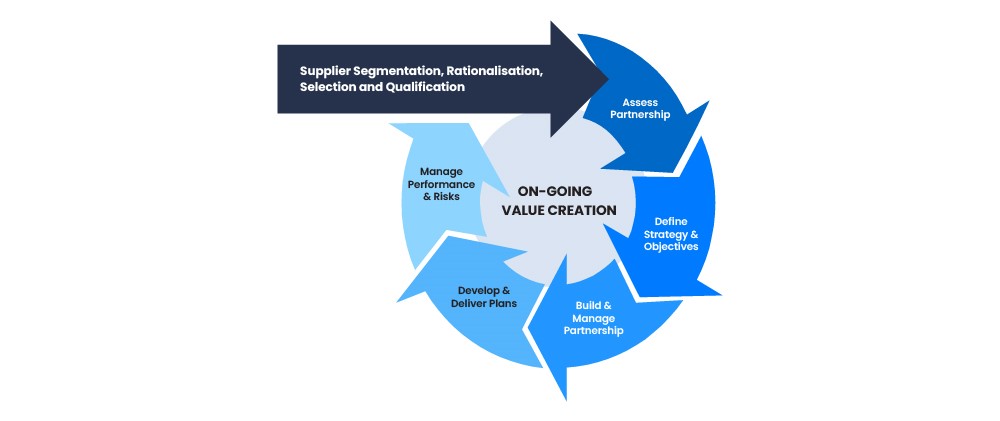

3. Preparing SRM Strategy for each Segment of Suppliers

An effective supplier relationship strategy should involve the following:

- Understanding and accommodating the interests of suppliers

- Ensuring timely payments

- Maintaining regular communication

- Setting up teams and processes

- Encouraging innovation and use of technology wherever possible

- Evaluating and monitoring supplier risks

That said, the relationships with different segments of suppliers are prioritized based on spend and how critical they’re for the business. Also, SRM managers should factor in unanticipated environmental conditions and keep a backup to ensure business continuity.

For instance, in December 2021, because of flooding in Canada and supply chain disruption due to the Covid-19 pandemic, McDonald’s had to ration French fries in Japan.

The common causes of supply chain disruptions are:

- Natural disasters like earthquakes, hurricanes, floods, etc.

- Epidemics and pandemics like the spread of coronavirus during 2020-21

- Shortage of drivers due to association-wide strikes creating logistics delays

- Product quality issues or price hikes due to non-availability of goods

- Cyber-attacks such as ransomware or data theft

4. Executing your SRM Strategies

Enterprises need to formalize SRM as a business process to successfully execute their SRM strategy.

It essentially involves

- Supplier segmentation tool

- Customer/supplier perception surveys

- Supplier account plans and alliance charter

- Performance scorecards

- Improvement charters

- Structured meeting templates

- Benefits tracking tool

The SRM program implementation relies on effective communication and the management’s ability to make data-driven decisions.

Ineffective communication may lead to missed supply dates resulting in missing production targets and poor supplier relations. Thus, SRM managers should communicate requirements verbally, in written emails, and through visual diagrams.

As you execute your SPM program, ensure you have the right tools to collect and analyze data. Typically, the following data points are used to measure supplier performance and strategize accordingly.

| Data source | Analytical insights |

| ERP | Delivery performance |

| CRM | Communication or responsiveness of suppliers |

| Quality control systems | Defect rates |

| Surveys | Service performance, innovation capabilities |

| Supplier self-assessment surveys | CSR performance, innovation capabilities, Risk status |

| External data sources | Market risks |

5. Measuring Supplier Performance (SPM)

SPM is an essential tool to understand your partnership with the supplier. Whether you’re buying goods or services, SPM typically addresses similar areas, such as:

- Timeliness

- Quality

- Productivity

- Adherence to regulatory compliance

- Other areas like innovation and social responsibility

Your supplier performance management strategy should be SMART. That is, Specific, Measurable, Achievable, Realistic, and Time-based. Below are some examples of how supplier performance is measured.

SPM goal: Improving product reliability

Example: N% reduction in customer warranty claims within X months

SPM Goal: Reducing operational cost

Example: N% price reduction resulting from approved vendor-initiated reengineering activities

Periodic reviews / audits are essential to ensure supplier performance is on track.

If the supplier performance is not as expected, SRM managers should take corrective actions and contribute to supplier development. On the other hand, good supplier performance should be rewarded.

SRM Tools

Supplier management tools help enterprises reduce operational costs, streamline processes and ensure transparency within the system. Cloud-based software for SRM adds accessibility and flexibility for the users. However, the choice of on-premise or cloud-based SRM software depends on the organization’s policies.

Organizations can go for comprehensive SRM tools like SAP or software that serve individual use cases like vendor onboarding, contract management, compliance, invoicing, etc. Below are the tools that support supplier management.

| Use Case | Functions | Software |

| Procurement | Procurement orders, supplier details, budget management, and the actual purchases | Precoro, Procurify, Oracle procurement cloud |

| Inventory management | Inventory optimization, auditing, and purchase order management | Oracle NetSuite, Unicommerce, Zoho Inventory |

| Spend management | Pay for inventory and supplies to different suppliers through different modes of payment, managing non-payroll business expenses | Spendesk, Airbase |

| Vendor onboarding | Automating supplier onboarding process | LeadSquared |

| Vendor management | Managing vendor relationships | SAP Fieldglass, LeadSquared |

| Contract management | Ensuring compliance | PandaDoc, Concord, ContractWorks |

| Communications | Managing interactions with suppliers | LeadSquared’s Manufacturing CRM |

| Quality management | Document control, change control, audits, corrective/preventive action (CAPA), etc. | MasterControl |

| Third-party risk management | Assess and manage supplier risks | OneTrust, UpGuard, ProcessUnity |

| Supplier performance management | Assess your supplier’s performance | ComplianceQuest, Corcentric, HICX |

| Internal and external surveys | Survey forms and sharable reports | Microsoft forms, SurveyMonkey, Typeform |

Note, the above tools are listed based on their reviews on platforms like Gartner, G2, and Capterra to give you an idea about the software available in the market.

In Conclusion

SRM is much more than simply negotiating a contract. Buyers and sellers must have:

- Trust

- Willingness to collaborate

- Commitment to relationship

- Transparent communication and willingness to share information

- Willingness to comply with the SRM process

Also, enterprises must invest in technology to take a calculated approach to their SRM strategy. Tools like procurement and spend management software, CRM, vendor onboarding software, etc., are of great help.

If you’re looking for software to onboard and manage vendor relationships, LeadSquared may be a good fit. Contact us to know more about it.

FAQs

SRM stands for Supplier Relationship Management. It is a strategy to build mutually beneficial relationship with suppliers or vendors.

In supply chain management, SRM refers to the approach of evaluating and managing interactions with vendors.

Some of the SRM challenges are:

1. Companies focusing too much on cost instead of values

2. Lack of SRM competencies

3. Unclear SRM objectives

4. Lack of alignment between business and procurement

5. Communication gap